SEQUIM — Sequim researchers said they have hit a major milestone for a potential energy source using household yarn, seawater and chemistry.

By flowing constant streams of seawater onto chemically-treated yarn, researchers with Sequim’s Pacific Northwest National Laboratory’s Marine Sciences Lab and LCW Supercritical Technologies of Moscow, Idaho, said they’ve collected about 5 grams of yellowcake, uranium powder used for nuclear power production.

Gary Gill, a Sequim researcher, said that once the technology is up to commercial scale — in about 10 years —the yellowcake can provide an attractive nuclear fuel for reactors.

Researchers said LCW, with early support from PNNL and the Department of Energy’s Office of Nuclear Energy, developed an acrylic fiber or yarn that draws in and absorbs dissolved uranium from ocean water.

Chien Wai, president of LCW Supercritical Technologies, said the yarn is regular, inexpensive yarn but chemically modified to absorb uranium.

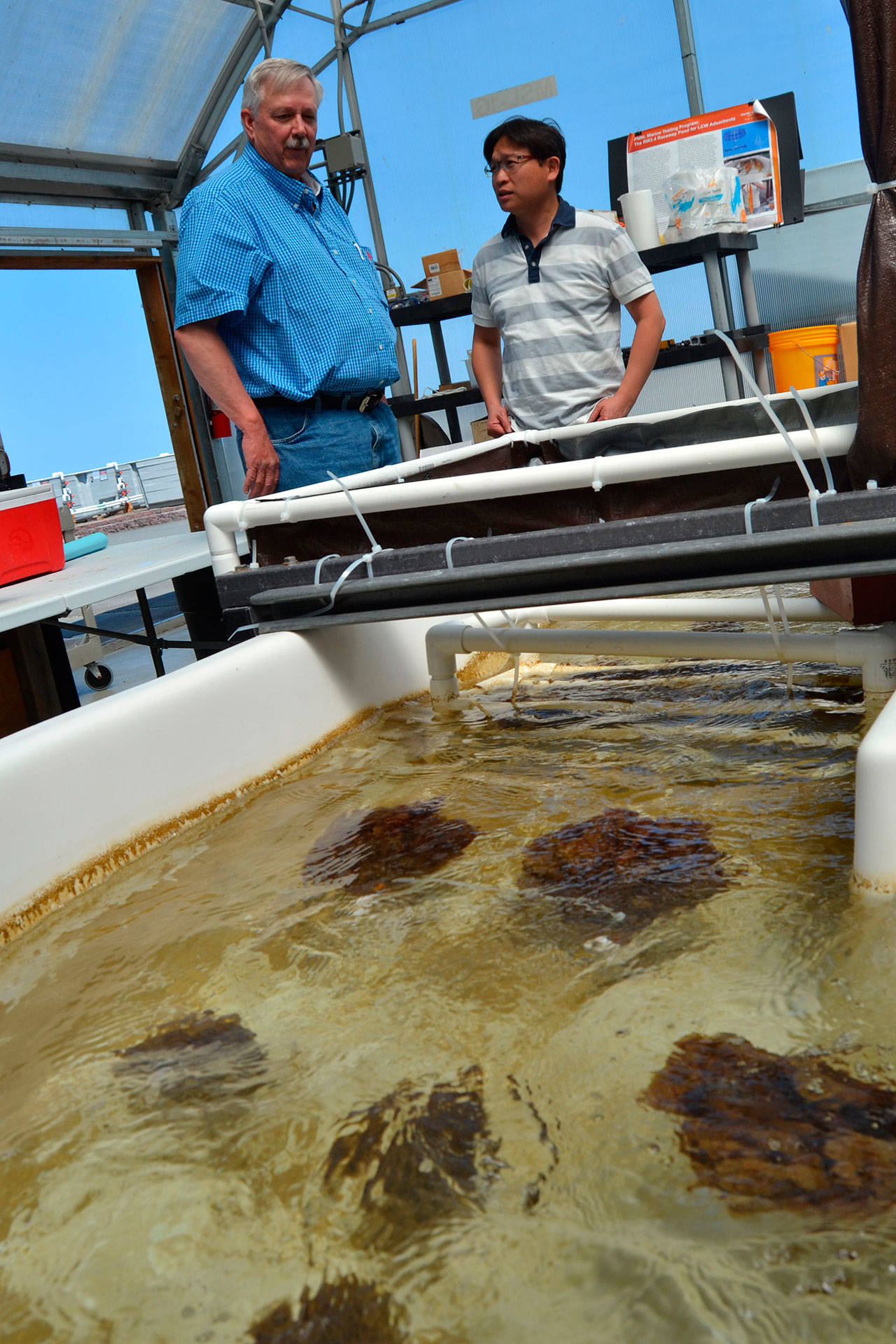

Gill said it took three experiments with multiple yarn strands in seawater to obtain 5 grams of uranium, an amount about the size of a nickle.

“We discovered not too long ago that temperature is an important parameter of performance,” he said. “The warmer the water, the more that it [uranium] absorbs out of the water.”

For tests, water was pumped into a tank from Sequim Bay into a large tub to mimic conditions in the open ocean, Gill said, and LCW researchers extracted uranium from the absorbent yarn.

At about 20 degrees Centigrade, they’ll obtain around 5 milligrams of uranium for every kilogram of absorbent yarn they put in seawater, Gill said, and that amount at least doubles in warmer waters at 30 degrees Centigrade.

For more “real world” deployment, Gill said LCW plans to work with Texas A&M University to test in the Gulf of Mexico.

Wai and his colleague Horng-Bin Pan previously worked on increasing domestic availability of uranium, and his new approach for absorbing uranium chemically binds the yarn’s acrylic fiber, and allows it to work in marine environments.

Captured uranium is easily released to be processed into yellowcake, Wai said.

Gill said he anticipates LCW sending more materials to Sequim this month for tests.

One of the primary drivers for extracting uranium from the ocean, Gill said, is that uranium resources in North America are limited.

“Easily obtainable resources will be gone and then we’ll have to go after much harder to get uranium in terrestrial mines,” he said.

“Secondly, most of the resources are not in the United States and in areas that aren’t as friendly where we don’t have the same control as a domestic resource.”

Dr. Li-Jung Kuo said the yarn is “much more sustainable” than mining uranium.

“I think it’s always good to explore a novel, greener technology to get an energy resource,” Kuo said.

Researchers said the chemically-treated yarn could compete with the cost for mining uranium. They said seawater contains at least four billion tons of uranium, which is an estimated 500 times more available in the sea than on land.

Wai said yarn fibers likely could absorb other metals in water and possibly clean up waterways too.

Some of those metals, Gill said, include vanadium, copper and zinc, as well as precious metals such as palladium.

“This was first developed for uranium but we realized we’re getting other things in [the material] too,” Gill said.

“So we’re looking at as a much broader spectrum and seeing what critical elements we can get out of seawater. The potential for resources is enormous.”

Now that researchers have hit the 5 gram mark, Gill said they plan to scale up.

“We’re quite a ways from selling anything commercial but we’re getting close to making the material itself for real world deployment,” he said.

While nothing is set yet, researchers envision a large area in the ocean similarly to kelp forests, about 50 square kilometers with yarn attached to the sea floor to attract uranium using currents.

“We haven’t gotten to the scale yet of putting large masses into seawater,” he said. “We’re working with one bundle of fibers and obviously we’d need to have thousands.”

Researchers will need to account for radiology, too, Gill said.

“It’s not a safety issue but an accountability issue,” he said. “We are extracting uranium which is radioactive.”

Once pulled out of the water, a Geiger counter wouldn’t register radioactivity on the yarn, but it certainly does on yellowcake, he said.

For commercial ventures, researchers envision ships traveling safely over the absorbent materials attached to the sea floor and boats being able to pick up the yarn every one-to-two months to extract uranium.

“It’s a passive deployment without electricity or any pumps that takes advantage of the ocean currents to deliver the uranium,” Gill said.

Implementation at a commercial level is about a decade away, Gill estimated.

For now, researchers in Idaho and Washington will continue to work on scaling up production to see if larger amounts of uranium is viable commercially.

Work began on the chemically-treated yarn yellowcake in 2012 and has received more than $7 million in funding so far through the federal Department of Energy, Gill said.

For more information about Pacific Northwest National Laboratory, visit www.pnnl.gov.

________

Matthew Nash is a reporter with the Olympic Peninsula News Group, which is composed of Sound Publishing newspapers Peninsula Daily News, Sequim Gazette and Forks Forum. Reach him at mnash@sequimgazette.com.